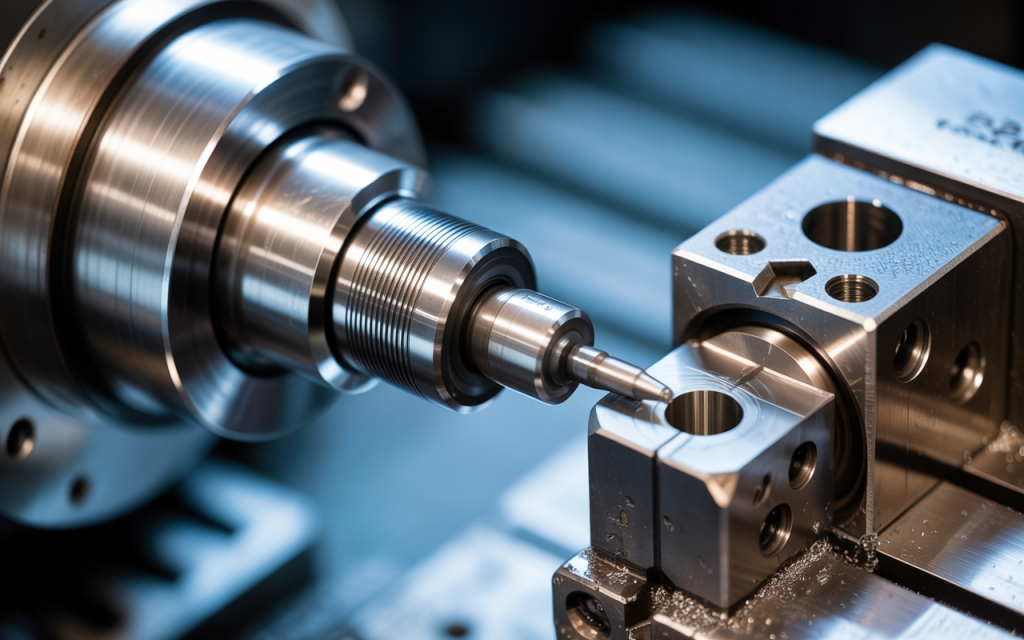

One of the first jobs I ever heard a machinist swear at was a simple shaft job. Nothing wild. Same part, repeat batch work, CNC turning operations all day. The shop was somewhere between Romford and Dagenham, one of those busy industrial areas.

The issue was not the insert. Not the program. Not even the material. It was the centre. They had swapped in a carbide tipped centre to “make it last longer”. Then the centre holes started to get marked, the runout control got worse, and the surface finish went rough. The parts still looked “close” until they went into the gauge. Then it was scrap. That day taught me this: carbide tipped centres are brilliant, but only when the job fits them.

This page is for production machinists and CNC operators who want straight talk on carbide tipped centres for CNC turning. When they help. When they hurt. And how to spot the trade-offs before you burn a day of production machining.

Quick meaning: what a carbide tipped centre really is

A carbide tipped centre is usually a type of dead centre with a carbide point. You use it in the tailstock support to give workpiece support. The carbide tip gives high wear resistance and helps keep rotational accuracy over long runs.

You will also hear people mix up terms like lathe centres, dead centres, live centres, turning centres. Simple way to think about it:

- Dead centres: the point does not spin on bearings. It relies on lubrication and contact geometry.

- Live centres: the point spins on bearings, often nicer for heat, but bearings can hate swarf contamination.

- Carbide tipped centres: usually dead centres with a very hard point, built for continuous operation and tough workshop conditions.

When carbide tipped centres are the right choice

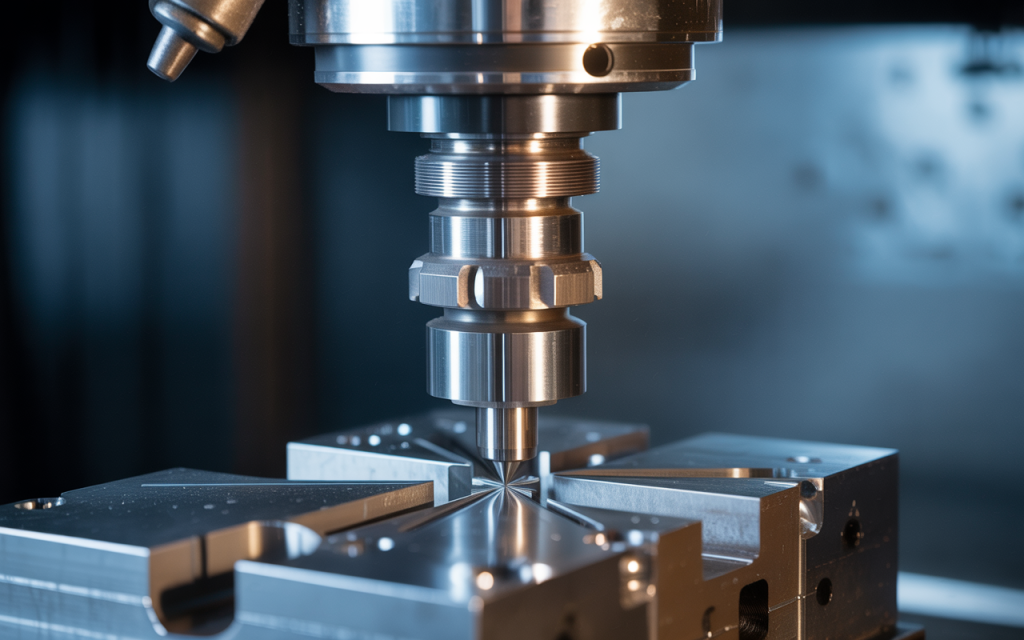

1) High RPM turning and long, steady runs

If you run high RPM turning with sustained spindle speeds, a normal steel point can wear, then your concentricity drifts. You might not notice until you measure a few parts and see dimensional drift creeping in.

A carbide tip is built for wear resistance. So for repeat batch work, it can hold runout control better across the shift. This is where carbide tipped centres earn their keep.

My opinion: If the job is high speed, stable, and you are doing the same part again and again, carbide tipped centres feel like the “calm” choice. Less point deformation. Less messing about.

2) Abrasive materials and dirty reality

Some shops are clean. Some shops are honest. If you do cast iron machining, or you deal with abrasive materials, fine grit exposure and cutting debris get everywhere. Add swarf contamination and you have a recipe for accelerated wear on the centre point.

Carbide stands up better to that. In production environments with contaminated materials, carbide tipped centres can keep surface contact stable for longer. That helps setup stability, especially when you need consistent centre alignment for a run of parts.

Also worth saying: this is not just “dirt”. Even a tidy shop can have tiny grit. Cast iron dust loves to find centre holes.

3) When you need stability more than comfort

Long slender work in CNC turning operations often needs tailstock support to avoid vibration resistance issues turning into chatter. When the centre point stays true, load distribution stays more even, and you have fewer surprises.

Carbide tipped centres can help with that because the tip holds its shape. If the point stays sharp and true, your contact geometry stays closer to what you set. That supports rotational accuracy.

4) Toolroom use that still acts like production

Toolroom use is not always “slow and careful”. Some toolrooms run like mini factories. If you have industrial machining that repeats a lot, carbide tipped centres can make sense there too. Less time re-dressing centres. Less time chasing runout.

When carbide tipped centres are the wrong choice

1) Shock loads, impact loading, interrupted cuts

Carbide is hard, but it can chip. If you get shock loads from interrupted cuts, or you have uneven contact because the centre holes are poor, tip chipping can happen. One tiny chip can become point damage, then your runout control goes out the window.

If you do work where the part “knocks” (impact loading), a carbide tip can take a hit badly. Steel may deform a bit, but carbide can fracture. That is a nasty trade-off.

My opinion: If the job feels rough, clunky, or unpredictable, carbide tipped centres can be the wrong tool. You do not want brittle in a fight.

2) Poor centre holes and sloppy setups

This is the big one. Carbide tipped centres do not forgive poor centre holes. If centre holes are rough, off-angle, or not deep enough, you get uneven surface contact and bad load distribution.

Then you get marking of centre holes, plus more vibration resistance issues. Also, if the setup stability is weak (tailstock not aligned, machine rigidity not great), the carbide point can get damaged fast.

If you are on a worn manual lathe work setup, or the tailstock is a bit “meh”, a live centre might be kinder. Or even a standard dead centre that you can recondition easily.

3) Light hobby lathes and low rigidity machines

Carbide tipped centres shine when the machine rigidity is there. On light hobby lathes, you often see more flex and more alignment drift. That creates shock loads and uneven contact. Again, that is where carbide tips can chip or mark the centre holes.

So yes, carbide tipped centres can be “too much” for small machines. Not because they are fancy, but because the whole system is not stable enough.

4) When heat control and lubrication are not managed

Dead centres need proper lubrication. If you run a dead centre dry, the surface contact heats up and you can get point damage. Carbide has good thermal stability compared to many steels, but heat plus poor contact geometry can still cause trouble.

In dirty shop environments, you can also get cutting debris stuck in the centre hole. That wrecks concentricity fast.

How to choose fast: a simple checklist

- High RPM turning + continuous operation? Carbide tipped centres often win.

- Abrasive materials like cast iron machining? Carbide tipped centres often win.

- Interrupted cuts, shock loads, impact loading? Be careful. Tip chipping risk.

- Centre holes are rough or inconsistent? Fix centre holes first, or pick a different centre.

- Machine rigidity and centre alignment are solid? Carbide has a better chance to pay off.

- Dirty shop environments with heavy swarf contamination? Carbide can last, but cleanliness around the centre hole still matters.

Two real shop examples (so this is not theory)

Example A: the “boring shaft” that prints money

A maintenance engineer I spoke to in Basildon had a steady job making shafts for a production line rebuild. Same diameters, same length, repeat batch work. They moved to carbide tipped centres and saw less point deformation and better concentricity over the week. Not magic, just fewer small problems stacking up.

That is the sweet spot: stable setup, good centre holes, steady speed, and long runs.

Example B: the “mystery chatter” on mixed stock

A small shop near Chelmsford took in mixed stock, some of it contaminated materials with grit and old paint. They used a carbide tipped centre and got vibration resistance issues plus marking of centre holes. The hidden problem was centre holes full of cutting debris and fine grit exposure. The centre point was basically grinding itself.

They cleaned up the centre holes, improved setup stability, and the same centre started behaving. That is the lesson: carbide does not fix messy prep.

Small local note: why this matters right now

Tooling costs have been noisy lately. Tungsten prices have been in the news, which matters because carbide is tungsten-based. When carbide costs jump, it makes the “cost vs longevity” question more real on the shop floor. If you can get longer life without scrap, carbide tipped centres can be a smart choice. If the setup is wrong and you chip tips, it is money on fire.

Safety and standards (quick, not preachy)

Turning work needs safe habits, especially around rotating parts and swarf contamination. The UK HSE has practical guidance on workshop conditions and control of risks. It is worth a skim even if you have been doing this for years.

HSE guidance on workshop risk controls (engineering)

If you like seeing what the wider UK manufacturing scene is focusing on, events like UK Metals Expo pull together CNC machinery, metalworking, and supply chain topics. Even if you do not go, the themes often match what shops are dealing with.

UK Metals Expo 2025 event info (GTMA)

Where Trio Tools fits in

At Trio Tools, we work with tungsten carbide tooling and precision parts made to drawings. So we spend a lot of time thinking about wear resistance, thermal stability, contact geometry, and the real trade-offs in production environments. Carbide tipped centres for CNC turning are a classic example of “right tool, right job”.

If you are not sure what is causing drift, runout, or centre hole marking, start with the basics: centre alignment, centre holes, and machine rigidity. Then match the centre type to the job, not the other way round.

Plain take-away

- Use carbide tipped centres when the work is steady, fast, and repeatable.

- Use caution when the job is rough, shock-loaded, or the centre holes are poor.

- Carbide gives longevity, but it does not forgive bad prep.